Granulation

(Wet Granulation, Extruder Granulation and Fluid Bed Granulation)

Granulation way (wet, extruder or luid bed) is chosen according to powder characteristics.

Direct or after granulation tableting is based on powder characteristic

(Wet Granulation, Extruder Granulation and Fluid Bed Granulation)

Granulation way (wet, extruder or luid bed) is chosen according to powder characteristics.

With cone mixing system, output verified to ensure effect and average

Tableting with high speed rotary machines. Conditions include maintained material potency, the least excipients and well-controlled weight.

Film pattern is chosen based on tablet types.

By Semi-Automatic Capsule Filling machines. Conditions include maintained material effect, stability and the least weight difference.

(Vertical Form Three Side Seal, Horizontal Form Three Side Seal and Fin Seal)

Powder filled into aluminium foil bag. Conditions include well-sealing, stability and the least weight difference.

Weight checking during production to control weight of output within allowance.

Checking appearance of tablets and capsules.

(Multi channel counting machine, Automatic capping machine, )

Automatic counting machine with precise system for quantity accuracy. Automatic capping machine and induction cap sealer for product stability.

Automatic counting machine with precise system for quantity accuracy.

Different from bottled and bagged packaging, every tablet/capsule is separated for best protect and easy to go.

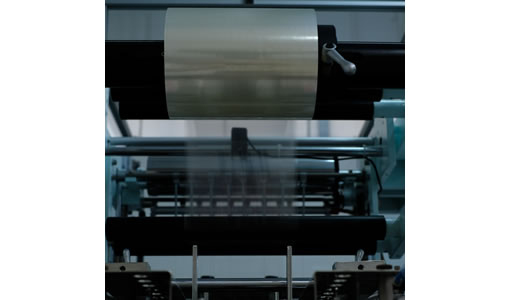

Overall packaging for nice looking includes labeling, printing, in the box, and wrapping in biaxially oriented polypropylene(BOPP) Film.